零件矫平机

矫平效果优异,效率出众

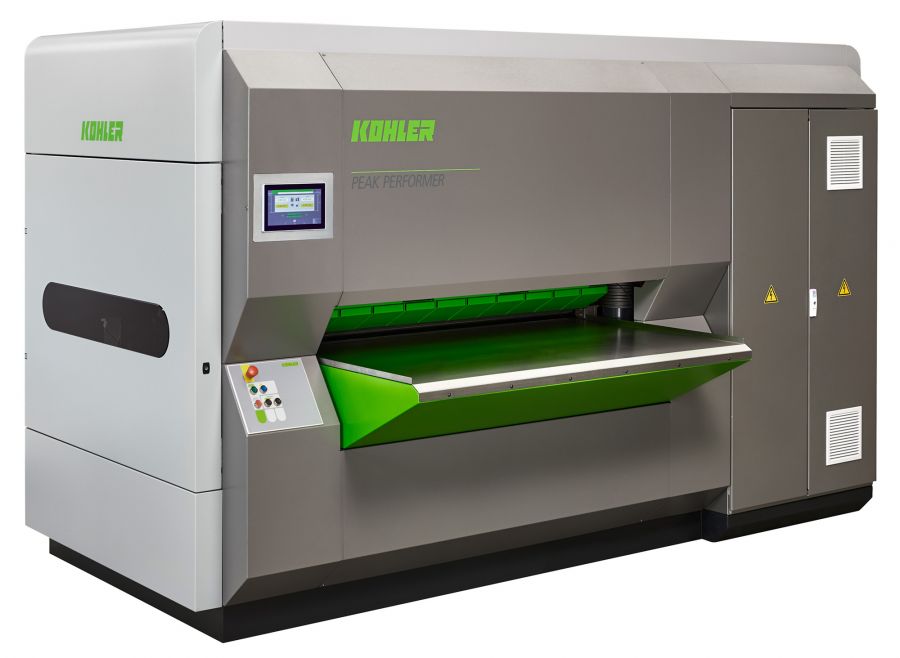

柯乐 Peak Performer 零件矫平机可实现可靠、精确的板材和零件矫平,消除所加工产品上的应力。下游生产过程将受益于高质量零件和板材矫平处理,因为工人无需再进行费时费力的返工。

产品主要优点:

- 无液压装置的伺服电气驱动的机床理念

- 机电矫平间隙控制(已获专利)

- 高级版的清洁系统

- 可逆转矫平辊(已获专利)

- 创新型控制系统

- 预见性维护

柯乐的零件矫平机无任何液压系统,这意味着,加上其出色的能源效率,此产品在工业钣金加工的节能方面发挥了积极的作用。柯乐因在无液压零件矫平机中使用直接驱动和机电矫平间隙控制而开创了全新的局面,并确立了其市场领导者地位。

柯乐 Peak Performer 零件矫平机可矫平厚度为 0.2 至 66 mm 的板材。

来自下列各行各业、注重质量的工业企业均信赖柯乐的零件矫平机。

- 汽车工程

- 建筑和农业机械

- 机械工程

- 钢铁服务中心

- 房屋建设

The importance of part leveling in metal fabrication

Flat parts can boost bending and welding productivity and keep customers happy

The sheet metal and plate that gets delivered to a metal fabricating company looks flat enough. But looks can be deceiving, and that is especially true with metal. What might seem flat at first is likely to lose its flatness during fabricating. This makes sense when you consider what happens to the raw material before it’s delivered to the shop. Sheets and plates come from the mills in coils. In metal service centers, these coils are uncoiled, straightened, and finally cut to length. Although the sheets appear to be flat, they still have stress inside. (The stress is evident in the material’s grain.)

What are metal fabricators to do to combat the stresses introduced during coiling and released after the parts have been cut or punched? This is where a part leveling machine can help. What are metal fabricators to do to combat the stresses introduced during coiling and released after the parts have been cut or punched? This is where a part leveling machine can help.

The Fabricator has published the fantastic article on "The Importance of Part Leveling in Metal Fabrication". Click on the link below to learn more.

Parts leveling on a KOHLER Peak Performer

Precise, efficient and cost-effective.

Whether with your own parts leveler from KOHLER or leveled on a contract basis at KOHLER: In many cases, this already pays off in the next production step such as bending, welding or assembly. Many different state-of-the-art Peak Performer part levelers are available in the KOHLER leveling center.

Perfectly leveled and deburred

One line, optimal results, seamless processing

Integrating a leveling machine and a deburring machine into a single production line offers numerous advantages. By combining both processes seamlessly, time, space, and energy are saved as parts are efficiently processed in a single pass. Simultaneous leveling and deburring ensure consistent quality and reduce the need for subsequent rework. This optimizes the entire production process, lowers costs, and increases productivity. Additionally, placing both machines in a single line allows for simplified control by just one operator, further streamlining operations.

Part leveling machine in steel processing

For level, low-tension blanks, sheet metal specialist DEUMU depends on the precise and efficient Peak Performer part leveling machine from KOHLER.

The Peak Performer 130P.2000 impresses with forward-looking features and guarantees optimum leveling results as well as flexibility, reliability and low operating costs. One of the decisive factors here is the ultra-modern servo-electronic machine concept and the complete absence of any hydraulics. This fact was one of the reasons why DEUMU opted for a KOHLER Peak Performer.

适用于激光和冲压零件的零件矫平机

典型应用:激光作业车间、装备制造、电子行业、飞机制造业、汽车制造业、贵金属处理器和定制应用

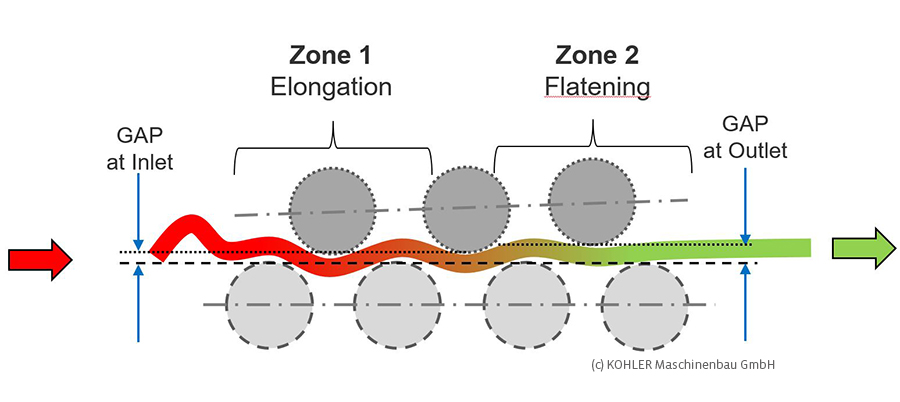

中小型零件的精密矫平。通过使用较小直径矫平辊、经优化的辊间距和超宽支撑辊,可获得出色的矫平效果。

我们的制造全金属飞机的瑞士客户 Pilatus Aircraft Ltd. 采用了 30.1250 型 Peak Performer 零件矫平机矫平钣金坯件。

适用于激光、等离子和冲压零件的零件矫平机

通常用于激光作业车间、钢结构建筑、机械和设备安装工程以及一般钣金生产中

适用性高的机床,可用于厚度高达 16 mm 的板材。凭借其获得专利的矫平间隙控制技术,该零件矫平机可以精确可靠地矫平所有常规材料。伺服电气驱动的机床理念可在完全不采用液压系统的情况实现。柯乐自主开发的高级版清洁系统可以快速轻松地清洁矫平辊和支撑辊。该机器还有其他优点,例如可逆转矫平辊、防夹功能、超宽支撑辊以及智能反向给料操作。

不锈钢专业企业 MODERSOHN® Stainless Steel 也信赖柯乐。该公司总经理、不锈钢技术专家 Wilhelm Modersohn 深知高精度矫平可带来质量提升。

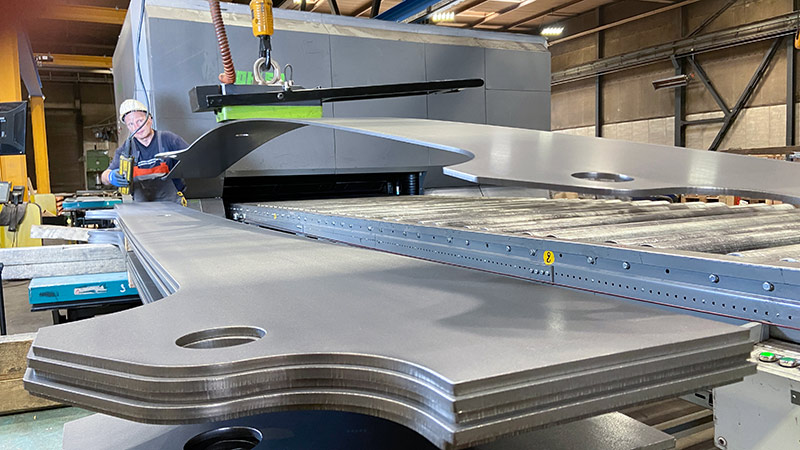

适用于中型和重型坯件及板材的零件矫平机

通常用于激光作业车间、火焰切割车间、重型机械和设备安装工程、铁路行业以及造船业

适用的材料厚度最高可达 65 mm。伺服电气驱动的机床理念打动人的是强劲的节能型直接驱动。该机器不但性能高,且运行和维护成本低。像所有柯乐零件矫平机一样,不使用液压系统。获得专利的矫平间隙控制可确保精确可靠地矫平所有常规材料。高级版清洁系统可以快速高效地清洁矫平辊和支撑辊。其他优点包括可逆转矫平辊、防夹功能、超宽支撑辊以及智能反向给料操作。

Liebherr-Hydraulikbagger GmbH 正在使用一台柯乐 Peak Performer 零件矫平机生产平整的、无应力的钢坯。柯乐制造的机器完全能够满足 Liebherr 专家的期望,他们非常高兴做了这个采购决定。

带有矫平辊弯曲功能的零件矫平机可有针对性地消除边缘或中间波纹

典型用于冲孔板材和面板

此类机器非常适合用于消除边缘和中间波纹,其原理是通过一个楔形系统单独或整体调节下部支撑辊支座,对矫平辊做预弯曲。通过提升和降低的变化可对矫平辊预弯曲进行控制。就像所有柯乐零件矫平机一样,这个先进的机床理念也不使用任何液压系统。

阅读报告“冲孔板材的挑战”:冲孔板材与未冲孔板材差别非常大。在制造过程中,孔会造成特殊应力和不均匀性。必须完全消除这些负面影响,才能让板材进行后续处理步骤。这给冲孔板材制造商造成了巨大挑战,但这个问题可通过适当的矫平技术和经验丰富的帮手予以解决。

纵列矫平生产线 – 加工圆形零件的完美组合

典型用于对平整度要求严格的所有圆形零件

纵列矫平生产线可一次在两个方向上矫平圆形零件并提供出色的生产效率以及平整度和同心度。

该生产线通过一个旋转工位将两台零件矫平机组合在一起。

柯乐 Peak Performer:

精确高效矫平

带有机电矫平间隙控制功能的无液压 Peak Performer 零件矫平机确立了柯乐在矫平技术方面以及业内的市场领先地位。

机器主要优点